When calibrating a device or an instrument, there are several important calibration characteristics to consider, including measuring deviation, hysteresis, and repeatability.

In this post, we will explore these Calibration Characteristics and discuss how to determine them in practice.

Measuring Deviation

Measuring deviation, also known as accuracy, is the difference between the indicated value of a measurement and the true value. It is typically expressed as a percentage of the true value or as an absolute value. Measuring deviation can be influenced by a variety of factors, including temperature, humidity, and electromagnetic interference.

To determine the measuring deviation of a device, you will need to compare its indicated values to a known reference standard. This can be done using a variety of methods, depending on the type of device and the desired level of accuracy.

For example, you might use a comparison method, in which the device is compared to a reference standard under controlled conditions, or a direct method, in which the device is calibrated directly against a reference standard.

Hysteresis

Hysteresis is the phenomenon in which the output of a device lags behind the input due to the history of past inputs. In other words, the output of a device may be different depending on whether the input is increasing or decreasing. Hysteresis can be caused by a variety of factors, including the physical properties of the device and the presence of magnetic fields.

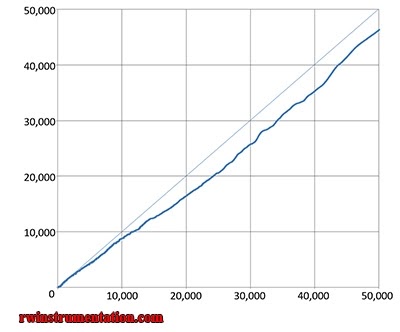

To determine the hysteresis of a device, you will need to measure its output under a variety of input conditions, both increasing and decreasing. You can then plot the output versus the input and look for any discrepancies between the two curves.

If hysteresis is present, the curves will not match, and the difference between them can be used to quantify the hysteresis of the device.

Repeatability

Repeatability is the ability of a device to produce the same output when measured multiple times under the same conditions. It is a measure of the consistency of the device and is typically expressed as the maximum difference between repeated measurements. Repeatability can be influenced by a variety of factors, including the skill of the operator, the stability of the environment, and the properties of the device itself.

To determine the repeatability of a device, you will need to measure its output multiple times under the same conditions. This can be done using a variety of methods, depending on the type of device and the desired level of accuracy.

For example, you might use a statistical method, in which the repeatability is calculated based on the standard deviation of the repeated measurements, or a range method, in which the repeatability is calculated as the maximum difference between the measurements.

Determining Calibration Characteristics in Practice

Determining the calibration characteristics of a device involves a series of carefully planned and executed steps. Here are some tips for determining measuring deviation, hysteresis, and repeatability in practice:

- Plan your calibration process carefully: Before you begin, it is important to carefully plan your calibration process to ensure that you are able to accurately determine the desired calibration characteristics. This may involve developing a detailed procedure, identifying the necessary equipment and reference standards, and selecting the appropriate measurement methods.

- Using the standards which can be traceable to the national or the international standards. To ensure the accuracy of your calibration process, it is important to use reference standards that are traceable to national or international standards. This will help to ensure that your measurements are consistent with those of other laboratories and organizations.

- Control the environment: The environment in which you are measuring can have a significant impact on the accuracy of your results. To minimize the impact of environmental factors, it is important to control the temperature, humidity, and electromagnetic interference in your measurement area as much as possible.

- Use appropriate measurement methods: There are a variety of methods that can be used to determine the calibration characteristics of a device, and the appropriate method will depend on the type of device and the desired level of accuracy. It is important to use a method that is appropriate for your specific needs and to follow the procedure carefully to ensure accurate results.

- Document your results: It is important to document your calibration results carefully, including the measured values, any sources of error, and any uncertainties. This will help to ensure that your results are accurate and reliable, and will also provide a record of the calibration process for future reference.

Please add your comments and inquiries here..